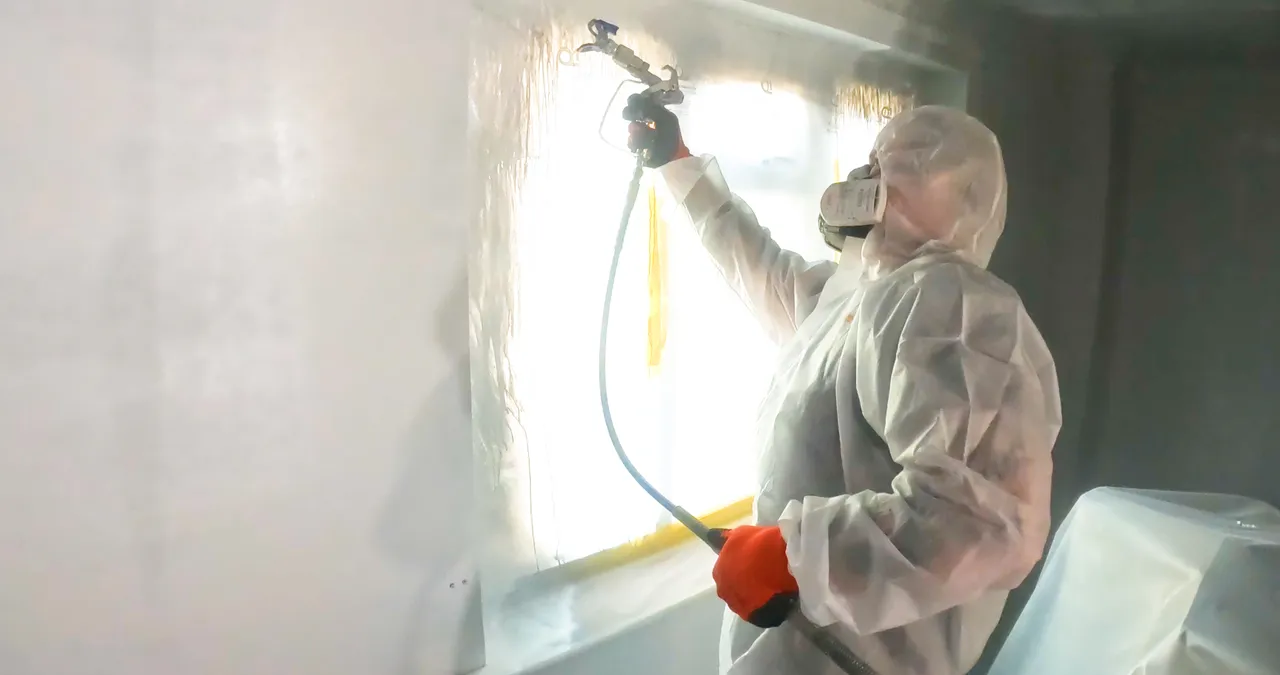

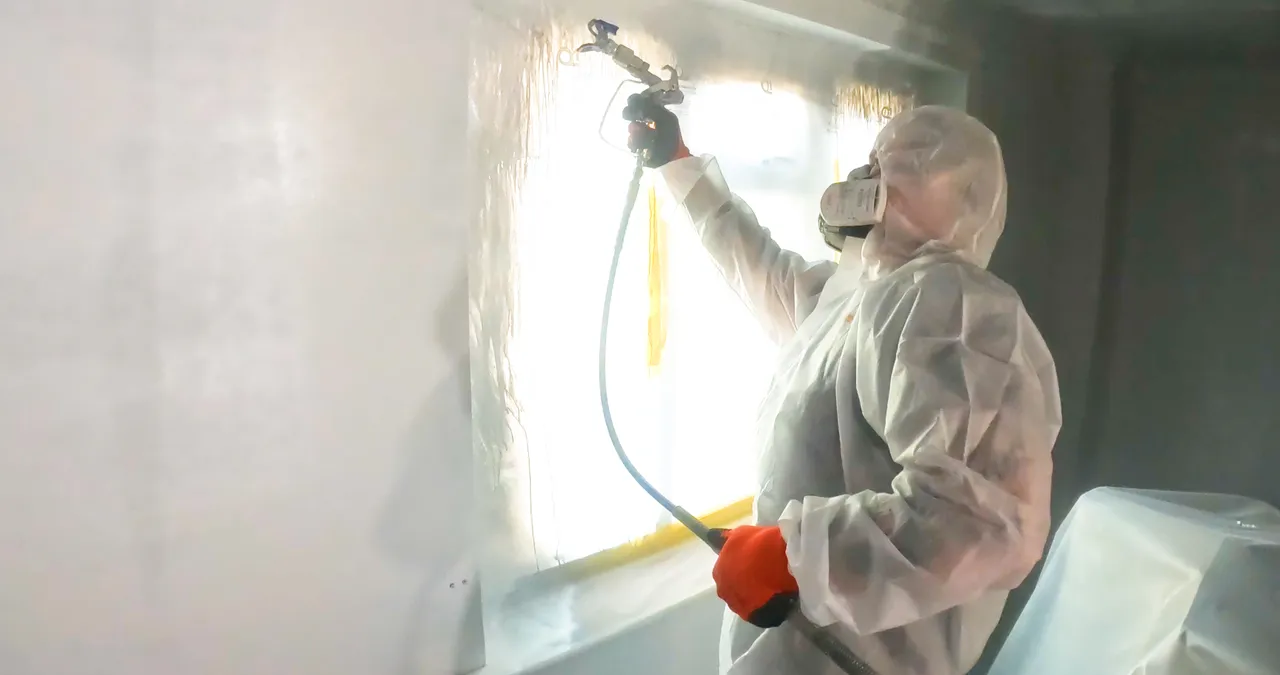

ThermaCote® - Applying It To Surfaces

ThermaCote® Being Sprayed Under High Pressure

ThermaCote® Being Sprayed Under High Pressure

Preparing Your Walls

- Surface Inspection & Cleaning

- Remove loose paint, plaster, or render until you reach a sound surface.

- Treat any fungal or mould‐infected patches with a biocide wash (if needed).

- Fill cracks wider than 1 mm with a compatible filler (e.g., cementitious or acrylic filler).

- Ensure: Wall is dry (≤ 16 % moisture content) and dust-free.

- Masking & Protection

- Cover windows, door frames, skirting boards, and light fittings with painter’s tape and drop sheets.

- Protect plants and garden features from overspray if working on external elevations.

- Priming (Base Coat)

- Stir Base Coat thoroughly; avoid introducing air.

- Use a high-density foam roller or airless spray (0.021″–0.023″ tip, 1,500–2,000 psi) to apply a uniform 0.5 mm film.

- Allow Base Coat to dry for 2–4 hours (temperature dependent).

Applying ThermaCote®

- Mixing TheramCote®

- Stir the product with 500ml of water until the consistency changes and the ceramic spheres remain evenly suspended.

- If tinting is required, add approved ThermaCote pigment and remix thoroughly.

- First Coat Pass

- Apply the first 0.5 mm layer of Thermacote® exactly like the Base Coat.

- Maintain wet edge to avoid lap marks.

- Dry time: 2- 4 hours (cooler UK weather may lengthen).

- Optional Second Top Coat

- In high‐heat‐loss zones or heat-loss perimeter, a second 0.5 mm Top Coat pass can further improve emissivity and R-value.

- Total coating thickness: 1.0 mm.

- We always check coverage with end-of‐day measurements (at least 500 µm thickness is needed for rated performance).

- Curing

- Avoid washing or painting over the coating for the first 24 hours.

- Full thermal performance is achieved within 48 hours once ceramic microspheres have fused to the substrate.

Note: If you’re unsure which tools we use, see How It Really Works for guidance on why spray yields the most consistent microsphere orientation.